At COP26, IEEE co-hosted a panel discussion, together with representatives from the European Business Council for Sustainable Energy (e5) and International Business Council for Sustainable Energy (ICSE). COP, or “The Conference of the Parties,” is a yearly conference that began in 1994 with 197 countries signing the UN Framework Convention on Climate Change. The conference gathers experts from around the world, from different sectors of society, stakeholders, governmental organizations, and experts from companies large and small.

At COP21 in 2015, almost 200 nations agreed to set the goal of keeping global warming below 1.5 degrees Celsius when they signed the Paris Agreement. This year’s COP was the moment when those signatories resubmitted their plans to reach that 1.5 degree goal. Leaders of over 120 nations attended this year’s COP in Glasgow, Scotland, along with over 30,000 government, business, and NGO representatives.

The panel co-organized by IEEE, which included professionals in business, research, engineering, and technology, brought a wide range of perspectives to bear on the topic. The discussion focused on the need for concrete action and participants delineated real solutions underway that will help us achieve the net zero target.

We need to start talking about what we are doing to reach the global net zero emissions target and where we are doing it, not what we might do.

Renewable Energy

Panel members remarked that the growth of renewable energy sources has been fantastic over the past years and cost is no longer an impediment to storage, noting that prices of renewable energy generation have come down by 90 percent over the last decade. At this point it is a matter of building it and scaling it out to see the effects, along with educating consumers and policymakers about its affordability. As we reach higher penetration of renewables, however, we still have some challenges to face. The intermittent nature of solar and wind power can present difficulties. Guaranteeing a supply of electricity is difficult when it depends on the sun to shine and the wind to blow.

Connecting renewables to the grid presents another challenge that is being overcome by grid integration. Moderator, Anna Freeman, Policy Director at Clean Energy Council in Australia, remarked that, while Australia has doubled the share of renewable energy within its market in the last five years, planning is needed in terms of how to integrate larger portions of renewable energy within the system. Panelist Bruno Meyer, a power grid expert and incoming Chair of the IEEE Technical Activities Board, observed that, with the share of intermittent energy sources increasing, we will need to adapt the energy grid. “So far, power grid operators have been able to meet the challenge,” he said, “but with the share of the power from intermittent sources increasing, we will need special technology to be able to guarantee security of supply. To do this, the power grid is fundamental.” Meyer noted that it will take work and innovation, but he was optimistic.

“So far, power grid operators have been able to meet the challenge, but with the share of the power from intermittent sources increasing, we will need special technology to be able to guarantee security of supply.”

–Bruno Meyer, Incoming Chair, IEEE Technical Activities Board

Meyer also mentioned that it is important to favor interconnection between grids, giving the example of Spain and France, who have managed to make it possible to export Spain’s excess wind and solar energy to France, with financial backing from the EU. In a similar vein, connection within countries can also be important, he said, giving Germany as an example. They have connected their wind-powered northern region with the densely populated southern part of the country, which was in need of energy.

Reaching Beyond Renewables: Sustainable Materials

Panelists stressed that there is more than one path to net zero and that more is being done beyond the energy space. Tariq Durrani, Professor, Department of Electronic and Electrical Engineering, University of Strathclyde and representative of IEEE, added that we need to consider the emissions from home building in order to help get to net zero, pointing out that 15.5% of emissions in Scotland come from this sector.

“Aluminium and cement cannot be decarbonized”, remarked Kolja Kuse, Chief Executive, e5. “Steel can, but it takes too much energy to do so. With new carbon sequestering materials, however, it is possible to move us even further toward net zero.” Panelist Professor Thomas Brück, Head of Werner Siemens-Chair Synthetic Biotechnology, Technical University of Munich (TUM) and fellow TUM researchers have developed a way to remove carbon dioxide from the atmosphere using algae. In this new process, after absorbing carbon dioxide emitted from steel processing, power plants, or the atmosphere, the algae is converted into algae oil.

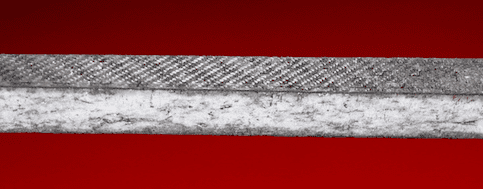

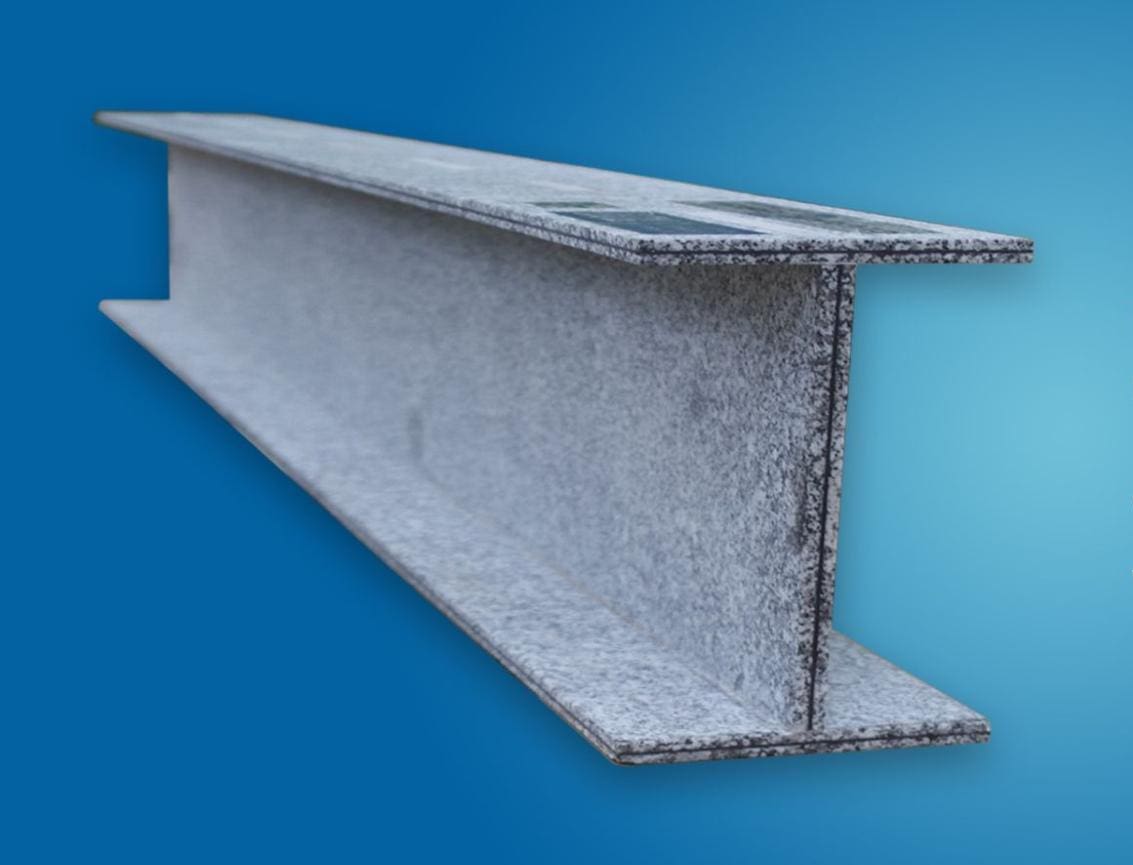

This oil can then be used to create a special carbon fiber material, invented by Kuse, that can be used in the building, aviation, and automotive industries and potentially transform those areas into carbon negative sectors. The carbon fiber material presents a safe way to store carbon, remarked Kuse, while also offering a lighter and stronger option to steel, cement, plastics, wood, and insulation. It saves energy by saving weight (lighter cars, for instance) and, at the same time, it provides a carbon sink. BMW is using the product in its i8 model; Airbus is using it for planes; and a T bar is being made as a substitute for steel or aluminum. Tom Jensen, CEO and Co-Founder of FREYER Battery, pointed out that if you fly a plane made of carbon fiber and use clean liquid fuel, this means that not only can you fly longer, but also fly with a lower carbon footprint in total.

Another algae-based material they presented is a mix of granite and algae-based carbon fiber that can replace steel or aluminum in things like solar frames, electric heating, and building. Kuse explained that not only does the granite composite outperform steel by a factor of two in terms of weight and pressure strength, but it takes two times less energy to produce compared to steel or concrete.

Carbon Fiber Stone (CFS) detail. Photo credit: Kolja Kuse

CFS I-Beam. Algae-based carbon fiber in combination with stone (CFS) is as light as aluminium and stronger than steel. Photo credit: Kolja Kuse

Energy Efficiency: Including all the variables in the equation

Participants shared their thoughts on energy efficiency and how we need to consider that as we are designing approaches and strategies to reach net zero. Increasing efficiencies will be a necessary aspect to achieving sustainability goals, given the dimensions of the problems we face. Meyer observed that to decarbonize the mobility sector in Germany would require the ability to produce 380 gigawatts of power, while the current primary production is only about 300 gigawatts. While we can devise ways to create more renewable energy, we can at the same time try to improve energy efficiency to tackle the problem from yet another angle. There are several ways we can think about improving efficiency:

Efficiency through choice of materials. As panelist Kuse explained, there is research and development being done to produce more energy efficient options for materials, and these can be employed to both act as a carbon sink while delivering lighter-weight materials, which can provide further efficiencies–a lighter car will require less energy to move than a heavier car, for instance.

Combining several approaches to increasing efficiency. ICTs and mobile technologies are looking to increase efficiencies as well, noted Durrani. They are massive industries and they produce 4 percent of greenhouse gas emissions. In the last 10 years, there has been a paradigm shift from lowering absolute energy consumption to increasing energy efficiency achieved through a combination of avenues–innovative systems design, improved software, more energy efficient hardware, and the use of AI to devise more efficient networks.

Efficiency as a cost-saving measure. When panelists were asked if they saw industry embracing energy efficiency as a first stop measure on the decarbonization journey, Meyer clarified that energy efficiency is more of a cost driven measure in industry, not a climate change concern. “In Germany we have one of the highest energy costs in the world,” he said. Additionally, legislators opt to regulate energy expenditure, forcing industry to look harder for ways to increase energy efficiency.

Pushing for efficiency based on a look at the full lifecycle. Jensen suggested that we need to look at energy efficiency from a higher level, one that considers the whole lifecycle, assessing the inputs and outputs generated from a given process. There is an overall view of how to assess this in the primary sector, but it is not well established to examine energy efficiency in the secondary uses. We need to employ life cycle assessment to look at not only the energy generated by a process, but the energy used in order to generate it. In other words, look not only at the benefits of, say, a clean material, but also assess how the elements used to make that new material were produced and procured. Or in the building sector, consider not only the materials, but also the energy usage by inhabitants.

Achieving efficiencies through the strategic deployment of our various options. Panelists agreed that solutions will likely depend on using a mix of technologies rather than a single solution and highlighted that it is important to prioritize where to use the various options. Not everything can be done through hydrogen, remarked Meyer. We need to be strategic as to where we choose to deploy it (and where we choose to deploy any of the strategies for that matter). Brück observed that liquid energy might be best deployed in use cases like aviation.

Incentives could encourage efficiencies. Jensen pointed out that the world cannot subsidize its way out of the problem we are in. We must also incentivize businesses and technologists to “get down on the cost curve and up on the performance curve.” “The pace of change is much faster, much better, than we realize and governments are increasingly putting tighter and tighter regulations in place, which creates, from an electrification point of view, positive feedback loops and ensures that we are on the right track. We need to invest a lot in batteries, wind farms, grid stabilization, etc. It is happening, but we just need to give the momentum more fuel…preferably energy.”

What more can be done?

Panelists agreed that we need to keep an eye on the full picture and note all of the options available, tailoring efforts to the specific industry, region, context, and use, while also looking to increase efficiencies wherever possible. They acknowledged that the road to net zero looks different depending on where you live. Countries with access to wind and water resources and access to funding to offer subsidies will have an easier time of it. Jensen pointed out that in Norway, they have abundant hydro power, which is flexible, and they have the funds to incentivize people to go electric, but this is not going to be the case in all countries.

Freeman observed that the massive economic transformation discussed by the panel will require countries to upskill and reskill, and asked Durrani, where the areas of greatest need lie and what we need to do to prepare workforces for the changes. He replied that “We need to produce the right kind of engineers for the future, engineers that understand what is meant by the ambitious target of net zero emissions and the importance of reaching net zero by 2050.” He observed that right now we teach in silos–mechanical engineers, electrical engineers, etc., and instead we need to teach a holistic approach to how we think about systems. Durrani noted that the Royal Academy of Engineering is leading an initiative challenging the way engineers are taught and trained, called Engineering Zero. The campaign is promoting the need for sustainability to become the central context across engineering higher education and skills provision, which will reflect what the net zero transition actually requires.

The good news is that we have the technology we need. Panelists agreed that we have the solutions, we just need to bring them together and see how to optimally combine them, improving as we go, while localizing and decarbonizing supply chains, to get to net zero.

“We have the tools and the strategies,” summarized Freeman, “now we must get to work.”

A recording of the session can be found at this link and more information on IEEE’s sustainability-related work can be found on the IEEE Sustainability webpage and in this Beyond Standards article on Sustainability and the WSIS Forum.

Author: Kristin Little